In today’s competitive apparel market, thermal underwear has become essential for combating cold weather—yet defective products cost global buyers over $240 million in 2024 alone (Source: Global Apparel Returns Report). With rising consumer complaints about pilling fabrics, false thermal claims, and even skin-irritating chemicals, how can importers ensure their shipments meet safety and performance standards?

As third-party quality inspectors, we’ve prepared a standard checklist for buyers’ reference.

- I. Basic Information

| Item | Details |

| Product | Thermal Underwear Set |

| Inspection Level | AQL 1.0 / S-4 (ISO 2859) |

| Sample Size | 32 pcs (for PSI) |

| Lab Test Samples | 5 pcs (Key items only) |

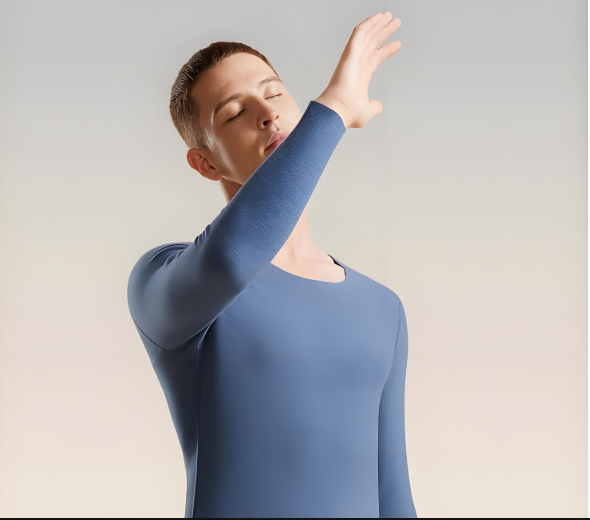

- II. On-Site Inspection (PSI)

- A. Visual & Workmanship

| Check Point | Acceptable Standard | Tool/Method |

| Stitching Defects | No skipped stitches, broken seams, or loose threads | Magnifying Glass |

| Fabric Flaws | No holes, stains, pilling, or uneven dyeing | Visual (D65 Light) |

| Printing/Embroidery | No misalignment (>2mm offset), fading, or cracking | Ruler + Rubbing Test |

| Symmetry Tolerance | ≤0.5cm (armholes), ≤1.0cm (body length) | Measuring Tape |

- B. Sizing & Labeling

- III. Critical Lab Test Items (Recommended)

| Test Item | International Standard | Buyer Action Threshold |

| Formaldehyde | ISO 14184-1 | ≤20 ppm (Infant) |

| pH Value | ISO 3071 | 4.0~7.5 (Skin contact) |

| Color Fastness | ||

| – Water | ISO 105-E01 | ≥3-4级 |

| – Perspiration | ISO 105-E04 | ≥3-4级 |

| – Rubbing (Dry/Wet) | ISO 105-X12 | ≥3级 |

| Thermal Insulation | EN 31092 (Rct Value) | ≥0.25 m²·K/W (Heavy) |

| Pilling Resistance | ISO 12945-2 (Martindale) | ≥3.5级 (After 5k cycles) |

Red Flag for Failure:

Carcinogenic dyes (AZO) detected per EN 14362

Shrinkage >5% after 3 washes (ISO 6330)

- IV. Defect Classification for AQL

| Defect Level | Examples | Critical | Major | Minor |

| Critical | Broken zipper, AZO dyes detected | ● | ||

| Major | Stitching unravels (>1cm), Size out spec | ● | ||

| Minor | Loose thread (<1cm), Minor pilling | ● |

- V. Supplier Documentation Review

Confirm below certificates are valid and matched to order:

OEKO-TEX® Standard 100 / REACH Annex XVII Report

ISO 9001 (QMS) or WRAP Certification

Lab Test Reports for Formaldehyde, Color Fastness, Insulation

- VI. Inspection Notes for Buyers

1.Pre-Shipment Sampling

Always test dark colors (black/navy) for color fastness – highest failure rate!

2.Banding Risk:

Check elastic cuffs with 3x stretch test – poor recovery causes banding.

3.Thermal Fraud Alert:

Suspect “fake thermal” if fabric weight <180gsm. Verify Rct value.

- VII. Download & Customization

http://For Full Checklist (PDF Version): [Email to Get Complete Checklist with Tolerance Tables & Test Flowcharts]

Why This Checklist Works for Global Buyers:

- Standards Conversion: Mapped GB → ISO/EN for international recognition.

- Risk Prioritization: Focus on top 5 failure items (per Amazon 2024 returns data).

- Actionable Thresholds: Clear pass/fail criteria for non-technical buyers.

- Cost Control: Lab test recommendations target high-risk items only.