As a third-party specializing in quality inspection, we assist importers in controlling the quality of their supply chain. Recently, we have sorted out the negative feedback data of hair dryer categories and discovered these high-frequency “minefields”, giving everyone a warning to avoid pitfalls!

1、 Core functional weakness

| Product Description | Air blower | |

| URLs of sources | https://item.jd.com/10109795993156.html | |

| Screenshots of consumer complaints |  | |

| Product defect details |  |  |

| Possible root causes | Some inferior fuses have impure materials or defective manufacturing processes, and their actual melting characteristics do not match the nominal values | |

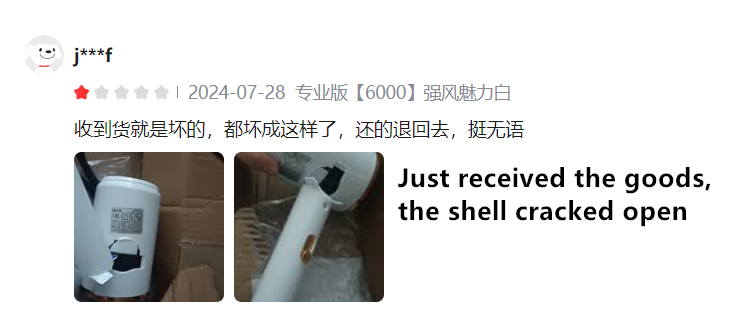

2、 Durability defects

| Product Description | Air blower | |

| URLs of sources | https://item.jd.com/10143259822103.html | |

| Screenshots of consumer complaints |  | |

| Product defect details |  |  |

| Possible root causes | -Insufficient material strength: using recycled PC/ABS alloy -Mold design defect: uneven wall thickness of the shell | |

3、 Experience the details and pull the hips

| Product Description | Air blower | |

| URLs of sources | https://item.jd.com/10143259822103.html | |

| Screenshots of consumer complaints |  | |

| Product defect details | / | / |

| Possible root causes | -Poor balance of wind turbine: low precision of impeller mold, eccentric vibration during rotation, noise exceeding 85dB -Air duct without noise reduction: straight tube air duct design, amplifying airflow disturbance sound | |

4、 Product design defects

| Product Description | Air blower | |

| URLs of sources | https://item.jd.com/10143259822103.html | |

| Screenshots of consumer complaints |  | |

| Product defect details | / | / |

| Possible root causes | -Unreasonable design of air inlet -Manufacturing process issues | |

Suggestions for importers to avoid pitfalls

1.Key inspection process for factory inspection: Focus on the qualifications of motor, temperature control, and wire suppliers, require the factory to demonstrate welding and assembly processes, and conduct 500 bending/plugging tests through sampling;

2.Stricter durability testing: Simulate 6 months of high-frequency use (such as 300 hours of continuous operation+500 drops), with a focus on temperature control and structural reliability testing;

3.Hidden costs need to be calculated clearly: short-lived products will increase the after-sales rate (we have calculated that the after-sales cost of this type of hair dryer is 2-3 times higher than that of high-quality products). Don’t sacrifice reputation for low prices

CQI solemnly declares:

Our CQI service mainly targets e-commerce operators who purchase goods from China or Southeast Asian countries, with a small number of orders per order.

With the assistance of our CQI inspection services, traders or exporters realize that customers have high requirements for product quality, and therefore, when purchasing and manufacturing products, they will supply customers with products according to the quality requirements of first-tier brands.

CQI has a global customer base covering most countries and has a ready-made service process to ensure that you can benefit from our inspection services quickly.

Contact us at quality@cqi5.com.cn, immediately to significantly reduce negative reviews and improve business efficiency.